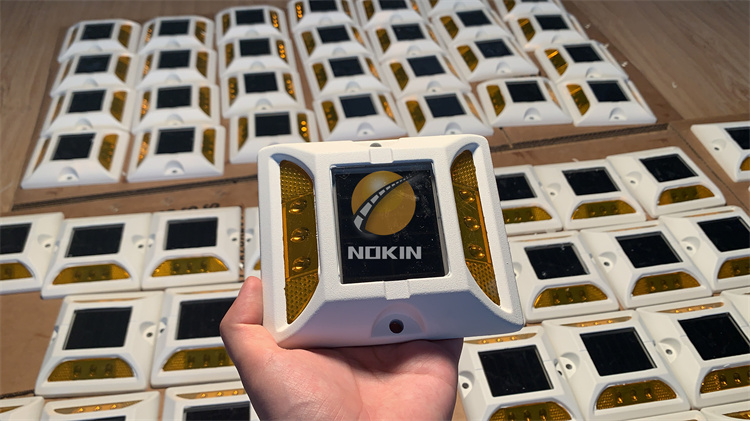

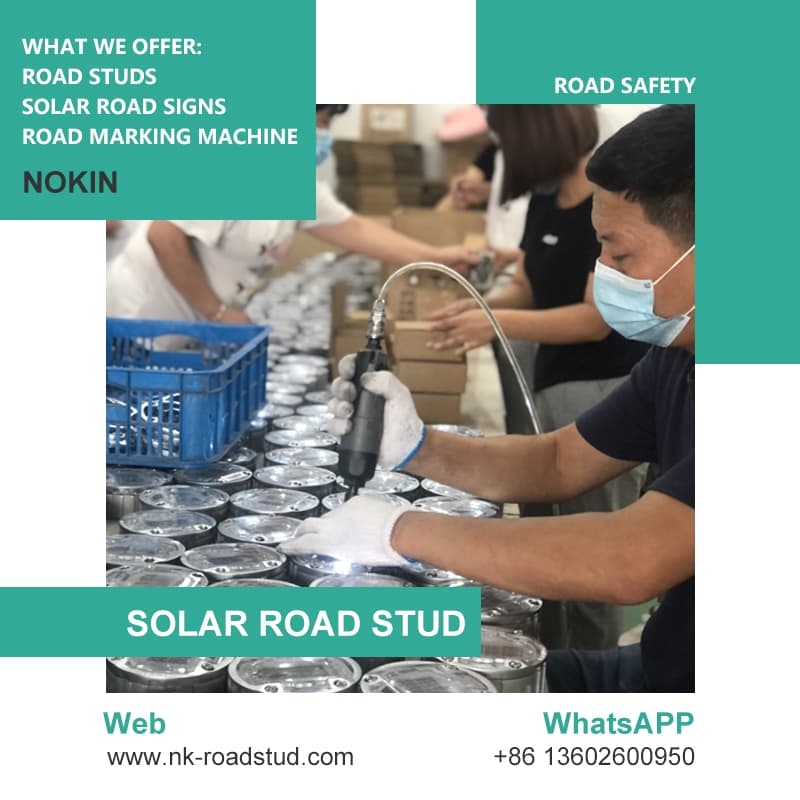

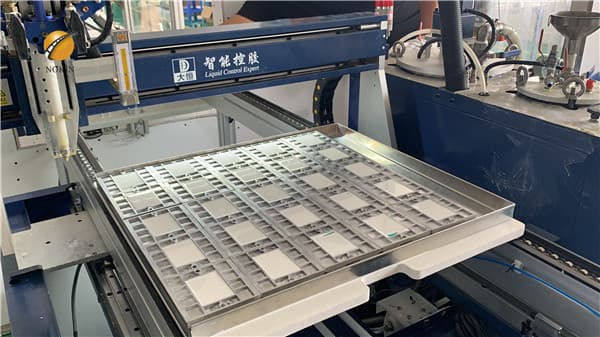

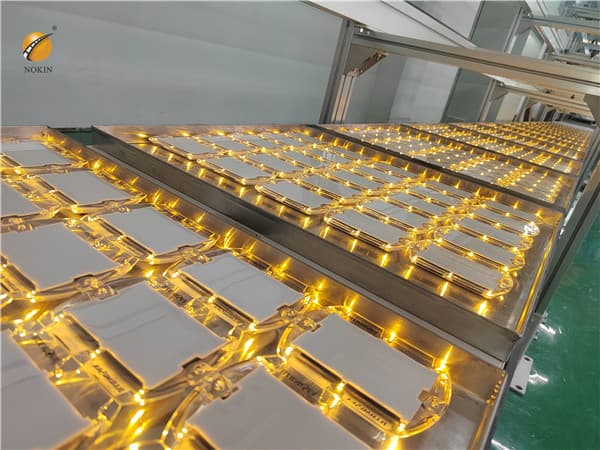

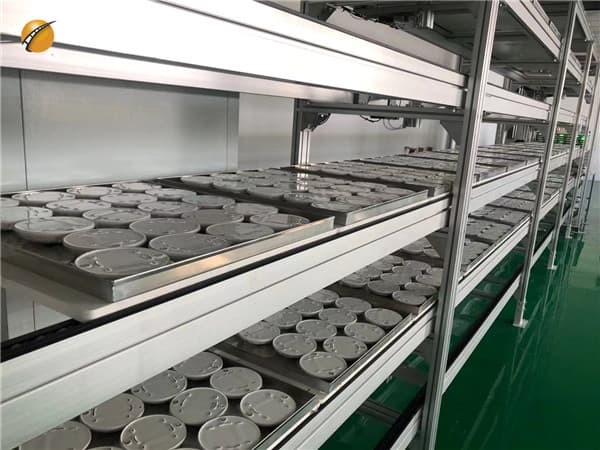

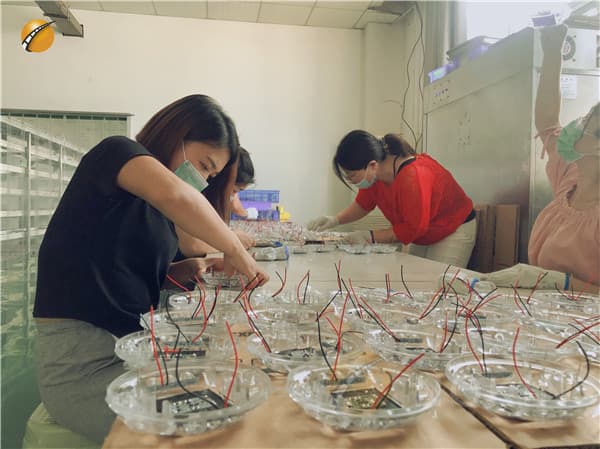

New Solar-powered road studs factory

In the wireless state, the technologies used in solar synchronous road studs mainly include the closed-loop control method, interlocking method, and short-period embedded control method. In the past, the technology already available in China was mainly a closed-loop control method, which is to set a master Control of the wireless emission source, set a receiver on the solar synchronous road stud, and use the wireless emission source to control the work of the solar synchronous road stud in its coverage area.

Send Inquiry

Quote Online

Share:

Content

In the wireless state, the technologies used in solar synchronous road studs mainly include the closed-loop control method, interlocking method, and short-period embedded control method. In the past, the technology already available in China was mainly a closed-loop control method, which is to set a master Control of the wireless emission source, set a receiver on the solar synchronous road stud, and use the wireless emission source to control the work of the solar synchronous solar road light in its coverage area. The current control radius of this method is usually within 50 to 150 meters, and the long-distance Synchronization is expensive and difficult to achieve over long distances. At the same time, it is also subject to radio frequency resources and the transmission power of the main control emission source.

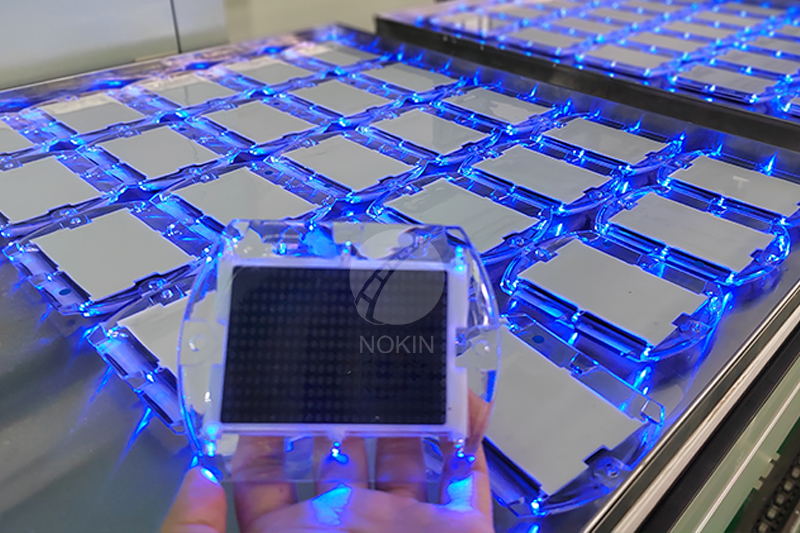

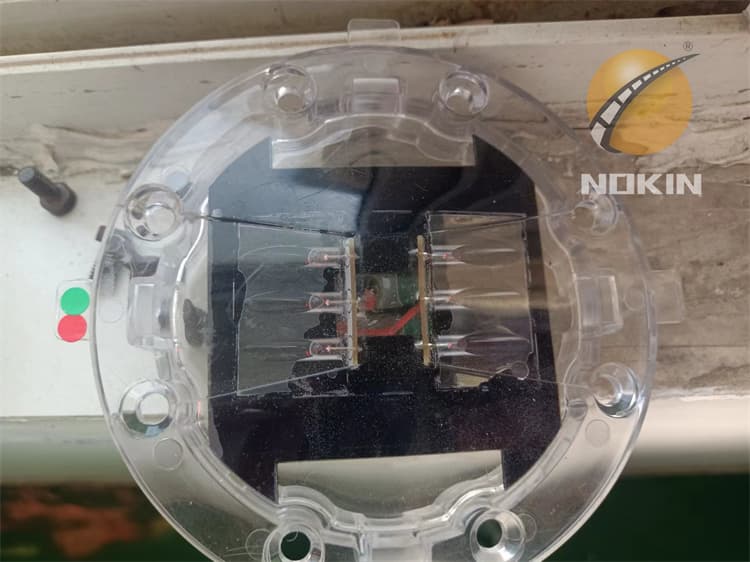

The second newer synchronization technology used in Solar-powered road studs is the interlock control method. This technology locks the working status of the solar synchronous road spikes through interlocking. This type of solar road maker usually requires about An interlocking period of 2 to 3 minutes. After the weighted interlocking is locked, the synchronization state can always be maintained. This technology can achieve chain synchronization within the line of sight, without the need for external control equipment, no synchronization limit distance requirements, and can be installed over long distances. According to actual measurements, the maximum error in the 10-kilometer section in 24 hours is less than 50 milliseconds.

Solar road studs can be divided into capacitive type and battery type according to different energy storage components. The service life of the former can reach five to seven years, while the service life of the latter generally ranges from one to three years. Because embedded solar road studs cause great damage to the road surface, and capacitive solar road studs are too expensive, raised battery solar road studs are currently the most widely used.

The former is generally used in the midline, and the latter is generally used in the edge line. This is because the solar road studs installed on the center line have particularly high-pressure resistance requirements. In order to solve this problem, the solar studs had to be buried in the ground, with only about 5 millimeters exposed. The solar road studs used on edge lines do not have particularly high-pressure resistance requirements and can still work effectively if they protrude from the ground.

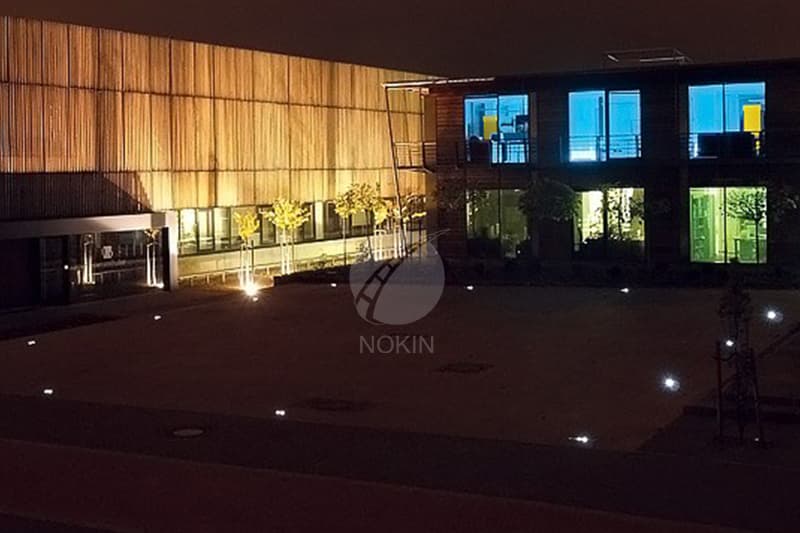

In short, as a new type of road safety facility, solar stud reflectors are of great significance in improving the safety of road users and promoting the development of environmental protection. With the continuous advancement of science and technology and the continuous expansion of application fields, solar road studs will play an even more important role in future road construction.

Inquiry

More