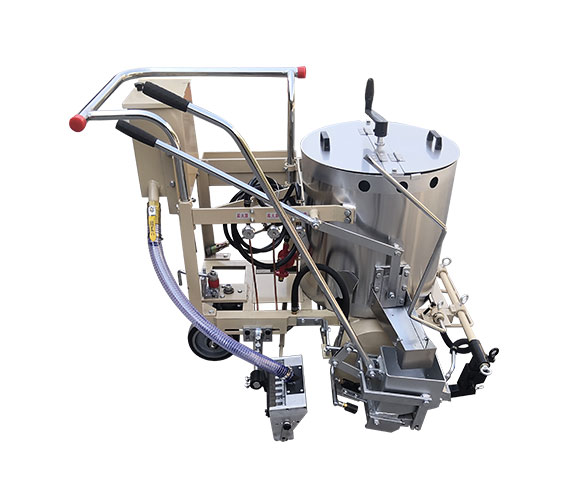

-- Arranged and durable hard tungsten alloy bottom knife, wear-resistant, heat-resistant, non-sticky, anti-deformation, easy to adjust; toothed-type knife bottom structure, tightly closed without leakage; flat line thickness and uniformity Straight, the head is neat.

--High-strength plate welding or aluminum die-casting material bin, high temperature resistance, deformation resistance, strong heat conduction and high heat preservation, ensuring consistent paint temperature in the hopper and solid connection with the bottom knife.

--Special wear-resistant heat-resistant wheel and punching rim, high temperature resistance, anti-wear, no deformation, no degumming, long service life and light walking.

--The variable-quantity glass bead spreading system is driven synchronously with the paint coating system, and the glass beads are spread more evenly.

-- The rear wheel can be locked, and the equipment walks more smoothly;

-- The whole machine electrophoretic coating or electroplating treatment, excellent anti-corrosion and anti-rust performance;

--By changing the hoppers of different sizes, it can meet the needs of marking construction of various conventional marking widths.

.jpg)