With the wide application of the solar road stud in highway and municipal roads, the quality problems and service life of the solar road stud have received more attention. In the actual application process, the phenomenon of solar road stud damage and reduced service life often caused by installation problems often occur.

Measure the performance of a solar studs on road from the following aspects.

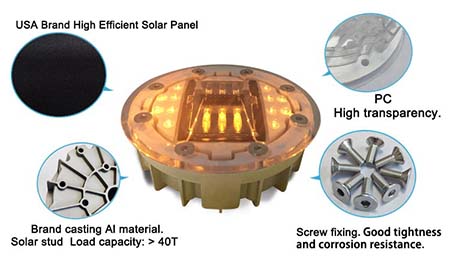

If the solar studs on road can not withstand a certain pressure, it will be easily broken after the car is crushed or impacted, and naturally cannot work normally, so the compression is a basic condition for the normal operation of the solar road studs. But the problem is that the solar road stud itself is an electronic product that contains electronic parts. It is not an easy task to make the electronic part have a higher degree of compression resistance. Therefore, the compression performance of the solar road stud is generally a little worse than ordinary road stud. However, with the development of science and technology, the solar road studs independently developed by Nokin have a compressive capacity of up to 30 tons and can be installed in the middle of the road.

There are several ways to effectively improve the compressive performance of solar road stud: one is that bare solar panels use PC ballistic materials to enhance the pressure resistance of the electronic part; the second is to use IC control as much as possible to reduce electronic circuits. The volume is to reduce the pressure on the electronic part; the third is to design some ribs on the shell to share the pressure on the electronic part.

If the solar stud on road is not completely sealed, it will water seepage, water seepage will cause short circuit, and the consequences are catastrophic, so a qualified solar road stud sealing performance must also pass text. There are several ways to improve the sealing performance of solar road stud:

(1) Separate design. The LED lamp cover and the internal circuit board are isolated. Even if the LED lampcover is broken, the interior of the solar road stud is guaranteed not to seep;

(2) Use strong neutral bonding material to ensure that the solar panel, LED lampshade and ball housing are tightly bonded without any gaps in between.

The solar road studs actively emit light and clearly outline the road. Compared with the reflective studs, one of the most important features is the high luminous intensity. The Ministry of Communications requires

2000 MCDs.