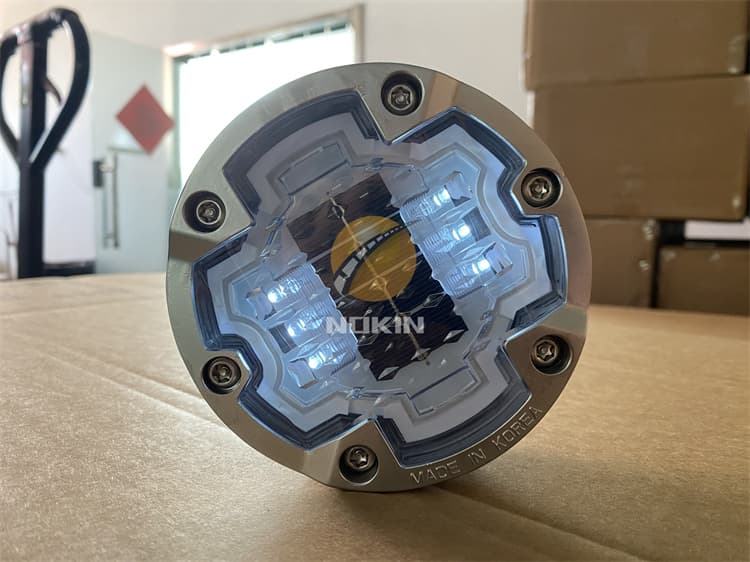

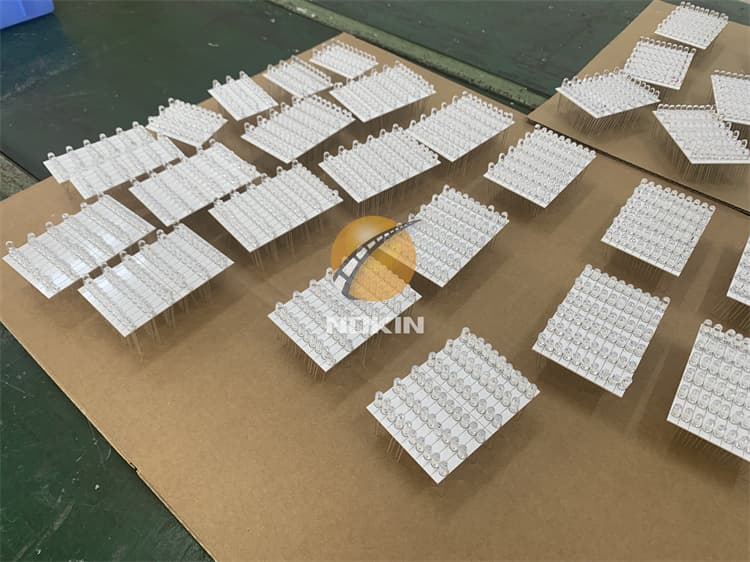

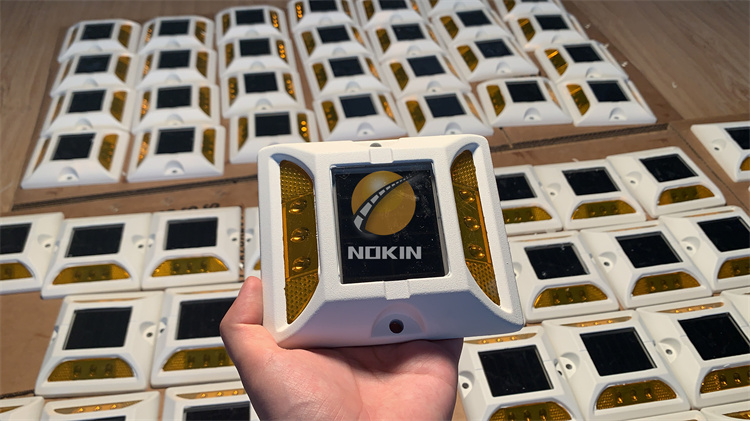

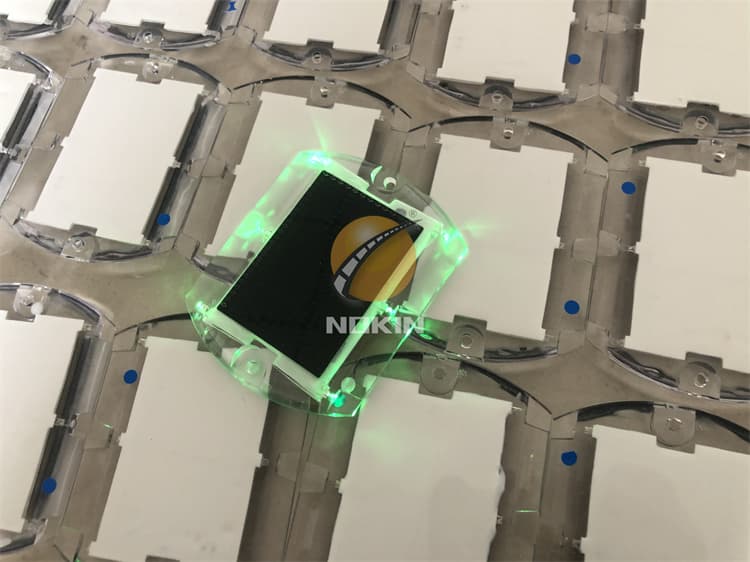

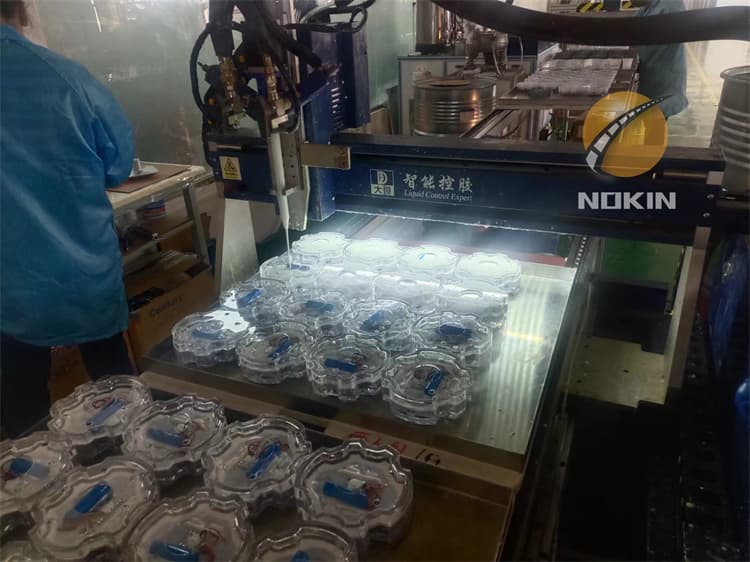

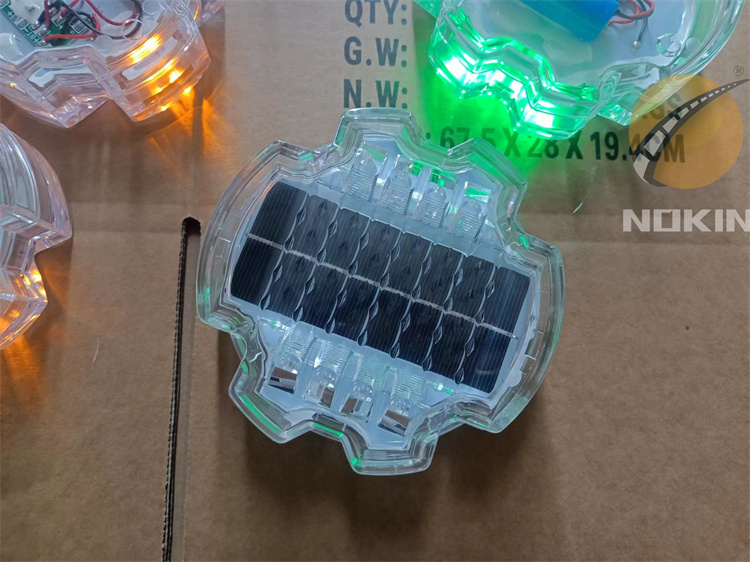

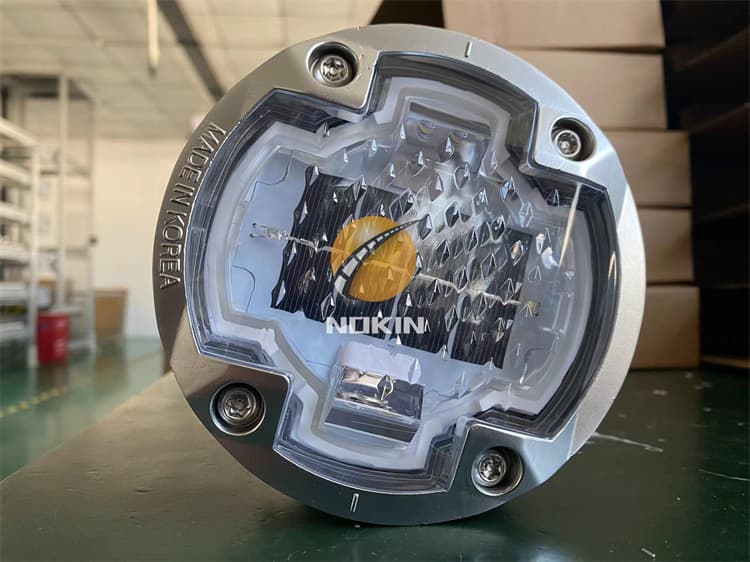

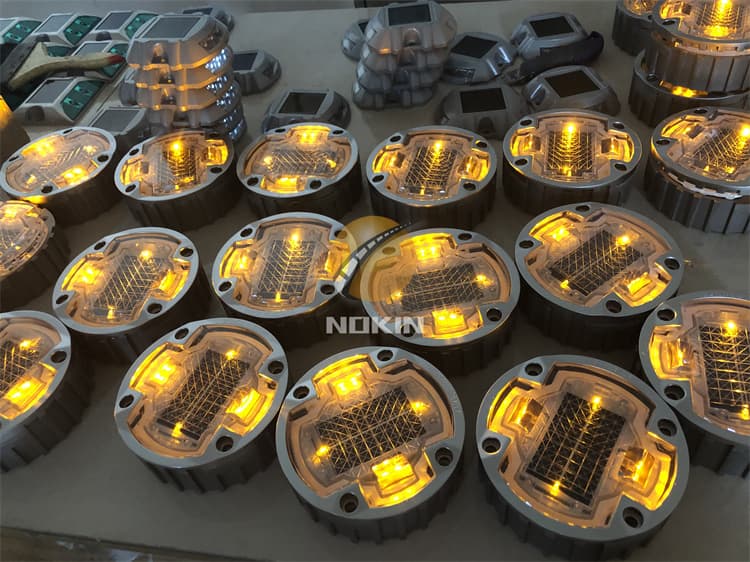

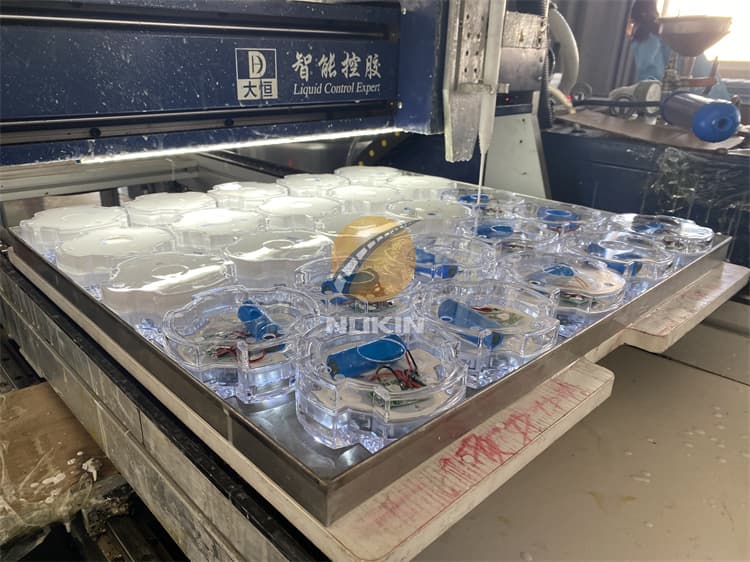

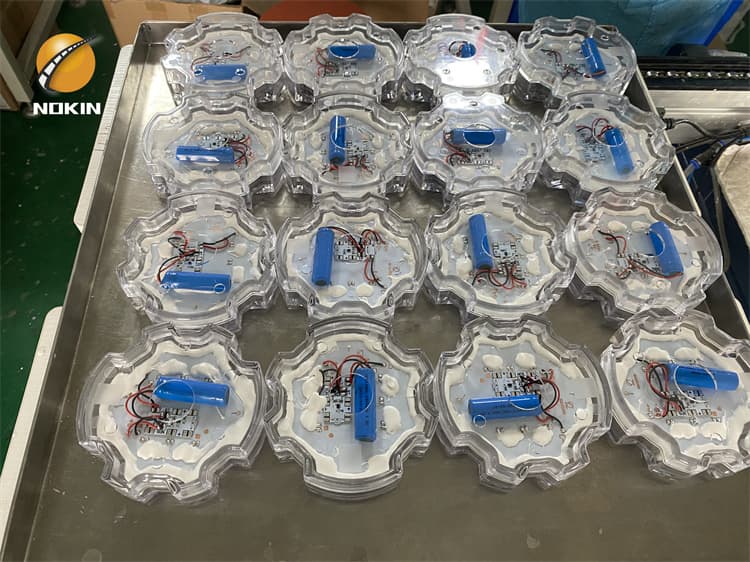

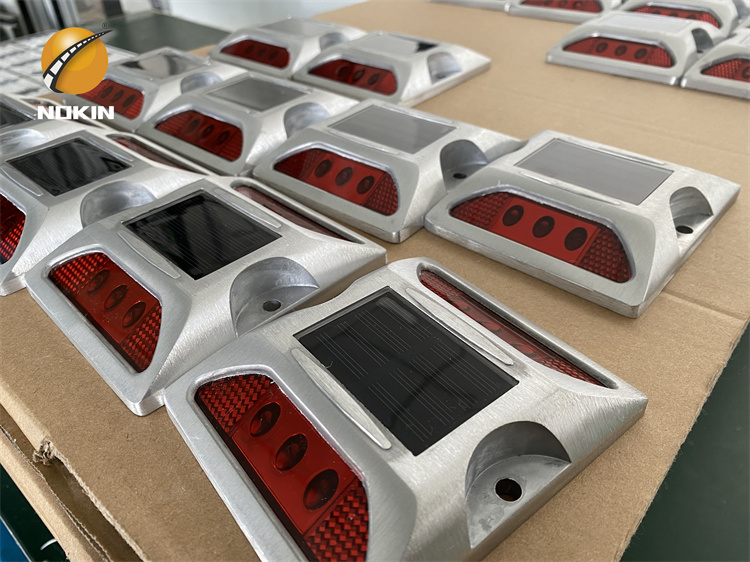

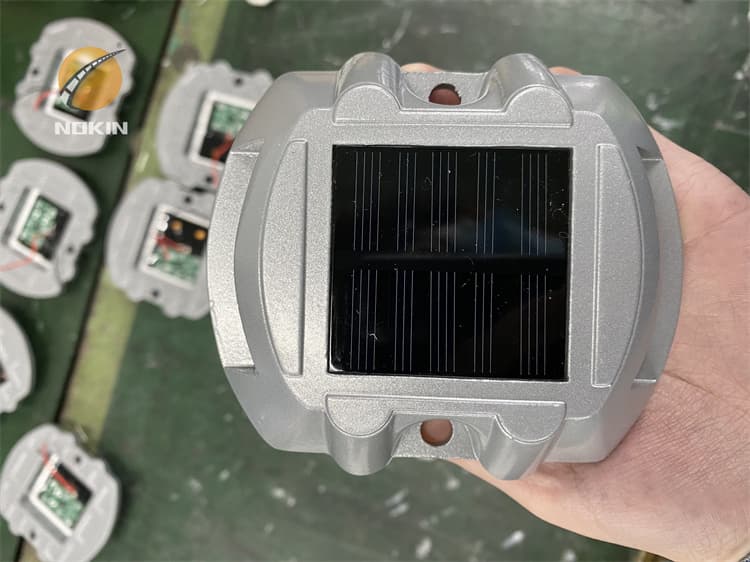

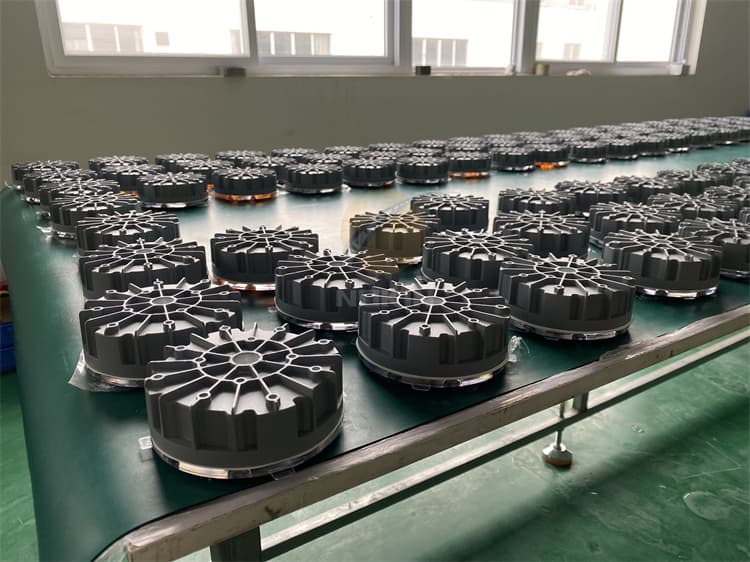

NOKIN Aluminum solar road markers bulk goods are being produced. Being robust and water-restrained, solar road markers are suitable to use on various pavements. It covers highways, expressways, dangerous entrances & exits, parking lots, petrol stations, commercial lanes, taxiways at airports, marine applications, etc.

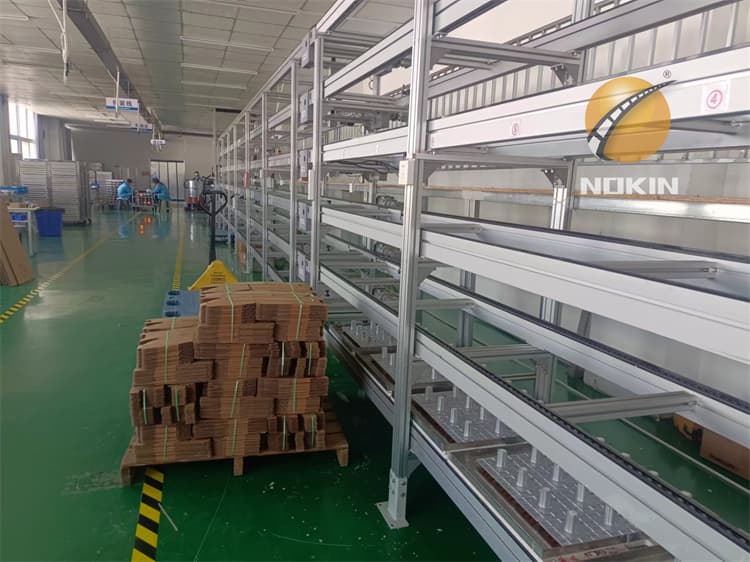

Shenzhen NOKIN traffic facilities Co., Ltd is an innovative technology company for overseas personnel. Professional institutions of professional and technical development in the road stud light and LED traffic products. Is a set of product development, production, sales, and integration of high-tech enterprises, the company’s main products are involved in solar traffic signal lamps, tunnel, tunnel-induced photoelectric products, solar road stud lights, and solar LED full sets of road signs instructions.

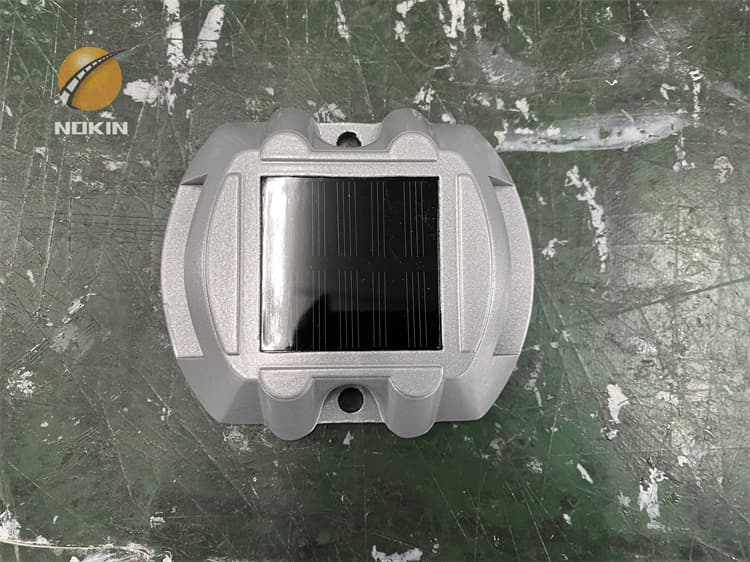

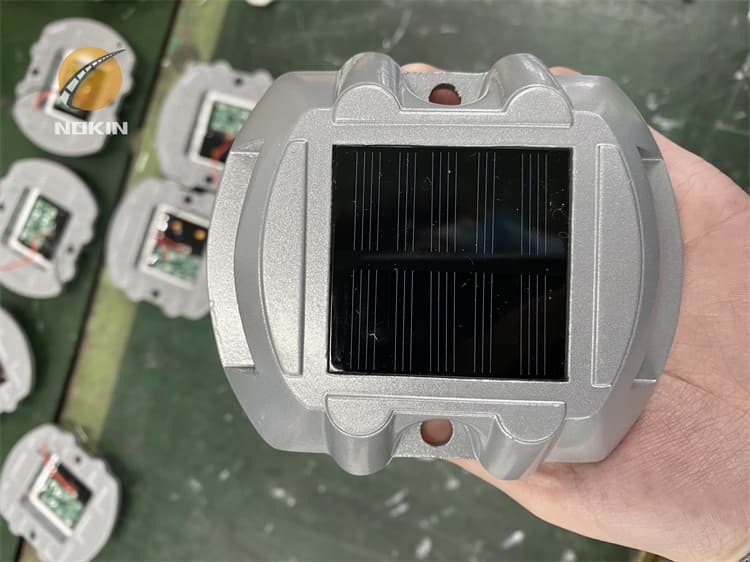

Specifications:

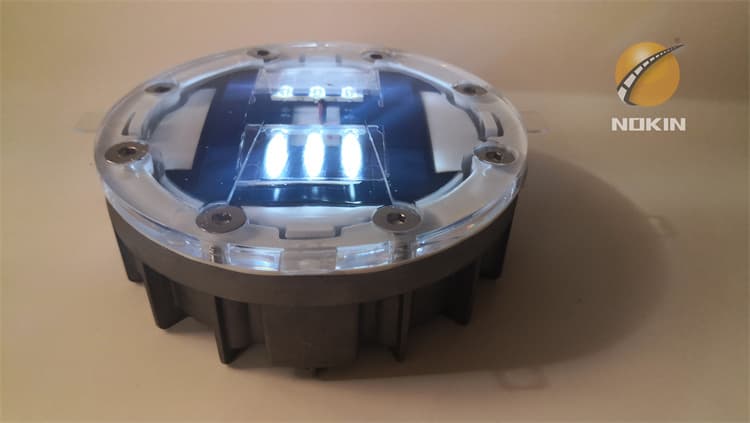

| Body material | Aluminum(GB-ADC12)+PC(Japan Brand) |

| Power supply | USA Brand High Efficient Solar Panel

2.5/150MA for NI-MH battery 5V/60MA for Lithium battery |

| Battery | NI-MH1.2V/600MAH(high-temperature resistance, Made in China)

Lithium battery3.2V/500MAH(Made in Japan) |

| Waterproof | IP68 |

| Visual distance | >800m |

| Life span | 2 years for NI-MH battery;

5 years for Lithium battery; |

| Load Capacity | >30T(can be installed in the middle of the road) |

| Size | L125mm*W107mm*H26+50mm (L4.92″*W4.21″*H0.98″+2.17″) |

| Package: | (without spike): 2pcs/box; 60pcs/ctn; Weight: 28kgs; Carton size: 67.5*28*20cm

(2pcs/box; 60pcs/ctn; Weight: 61.73bs; Carton size: 26.57″*11.02″*7.87″) (with spike):1pcs/box; 45pcs/ctn; Weight: 30kgs; Carton size: 66.5*44*28cm (1pcs/box; 45pcs/ctn; Weight: 66.13bs; Carton size: 26.18″*17.32″*11.02″) |