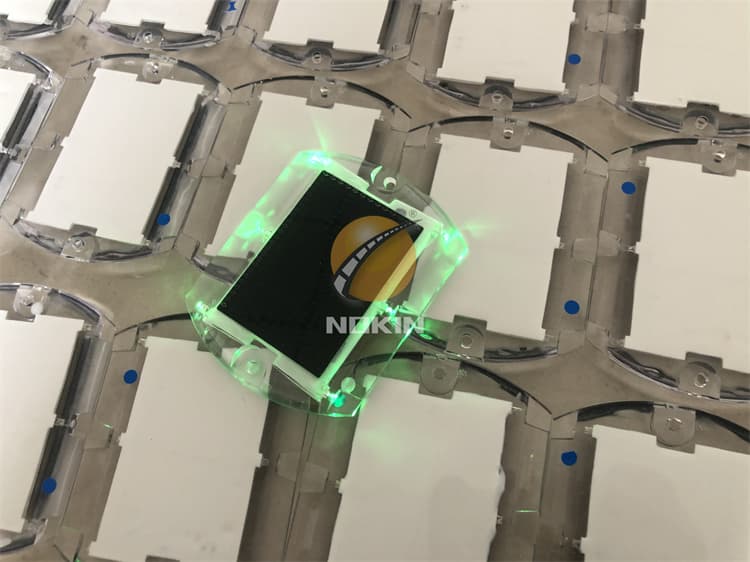

Solar Cat Eyes Road Stud Synchronized For Urban Road

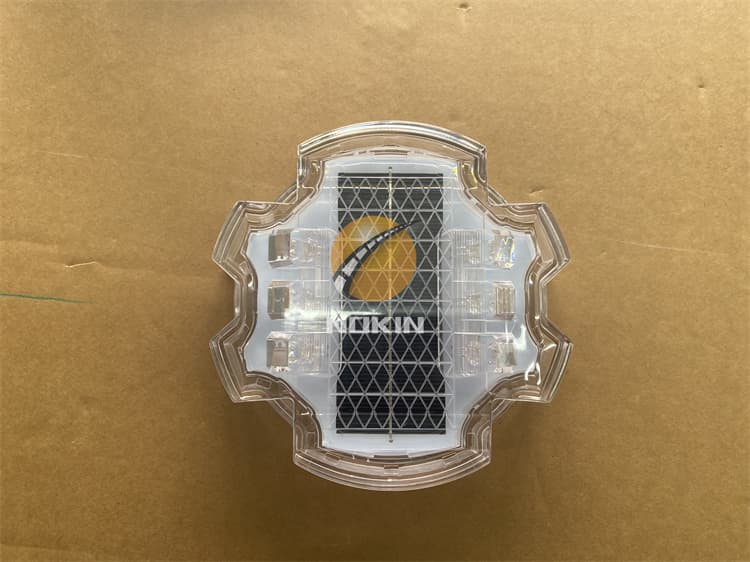

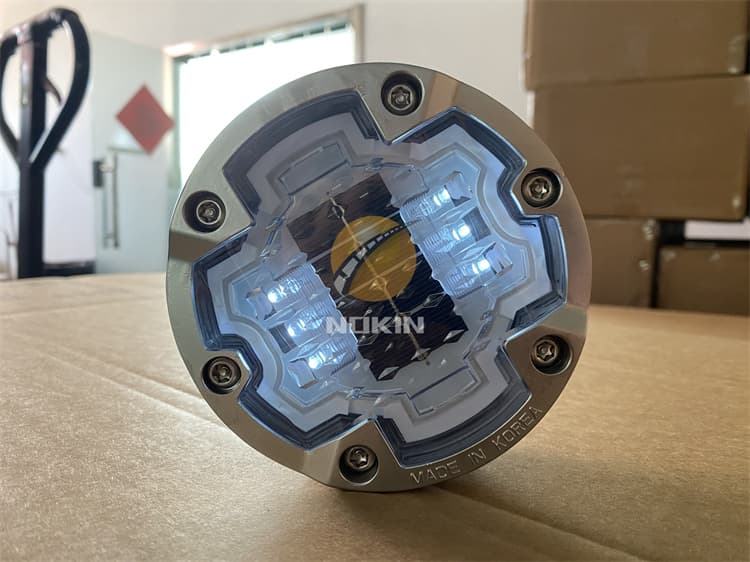

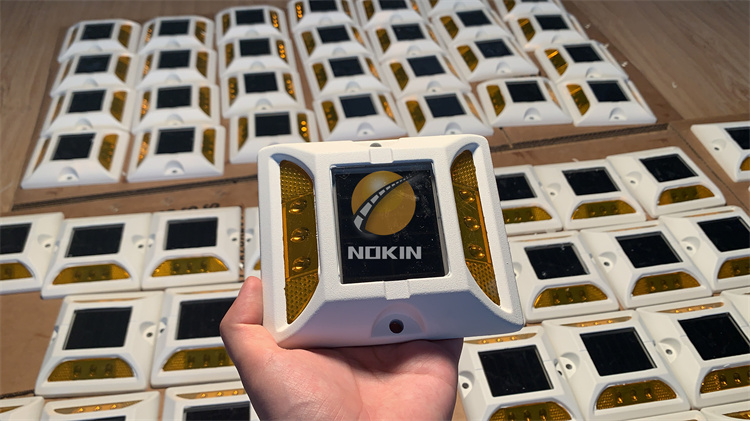

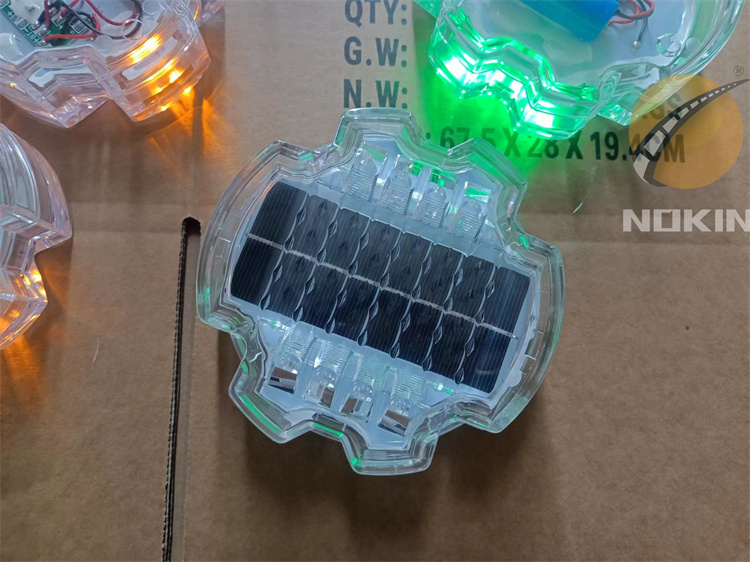

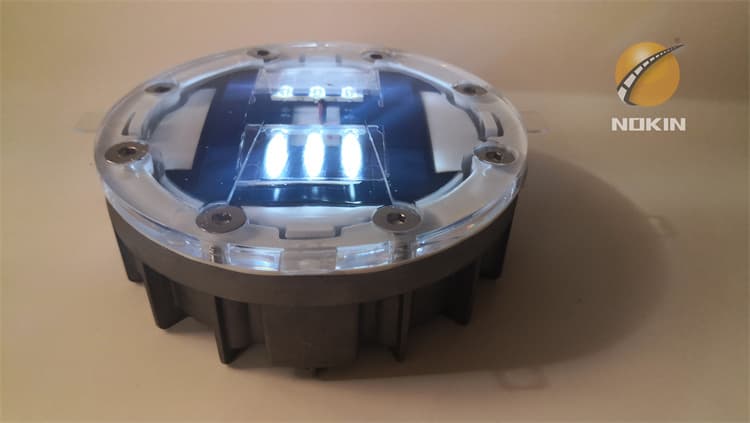

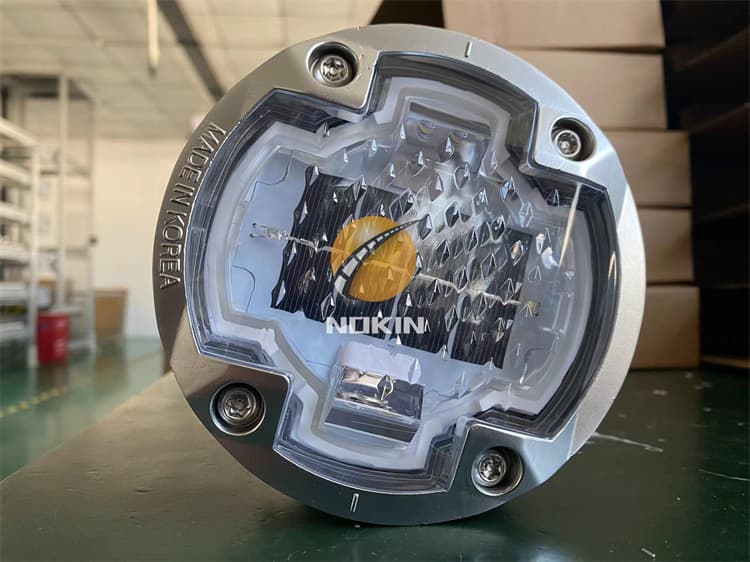

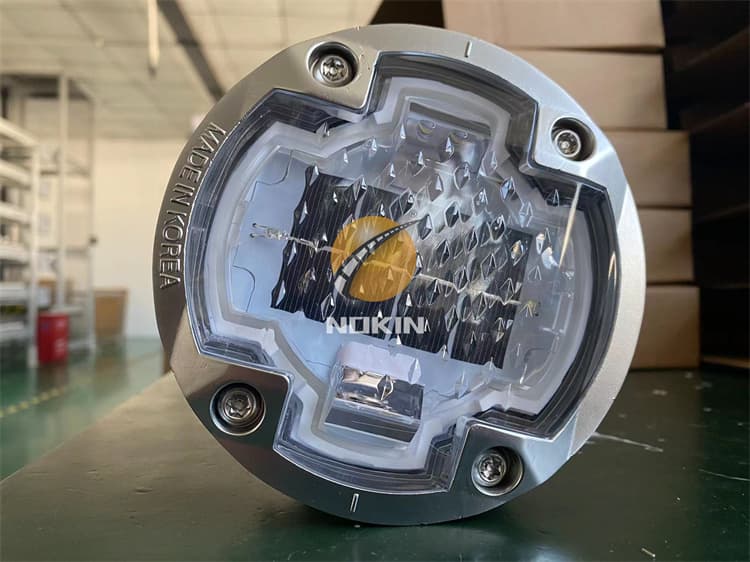

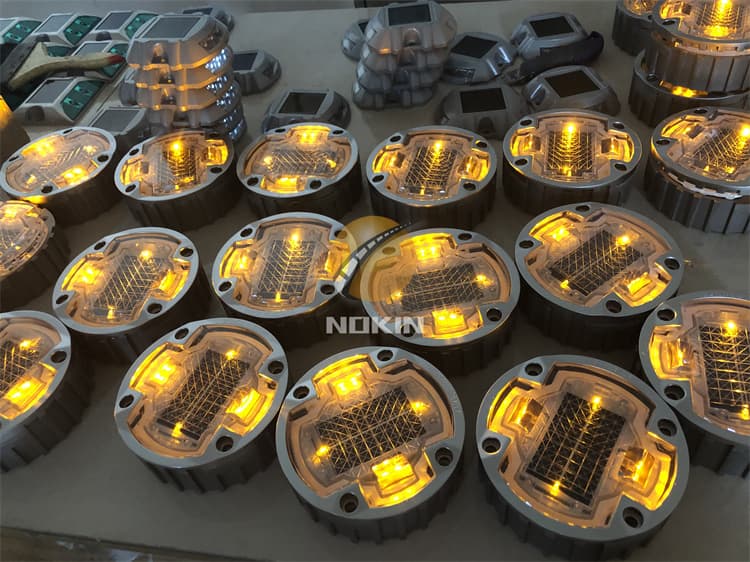

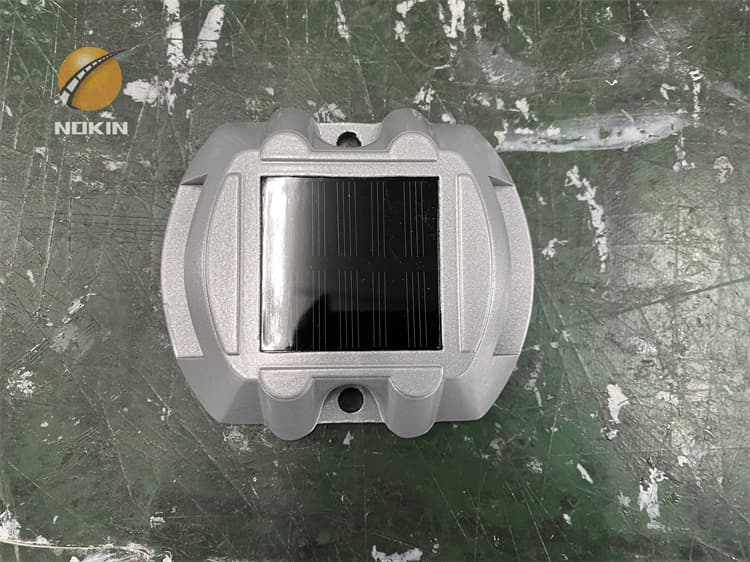

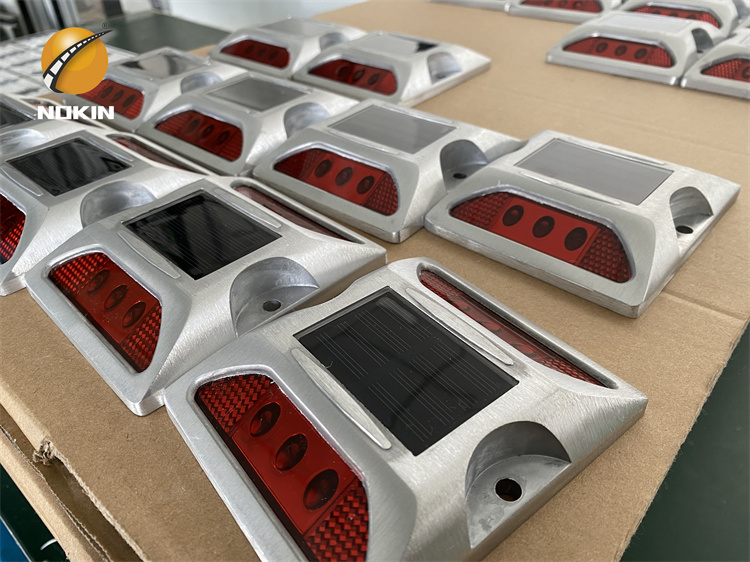

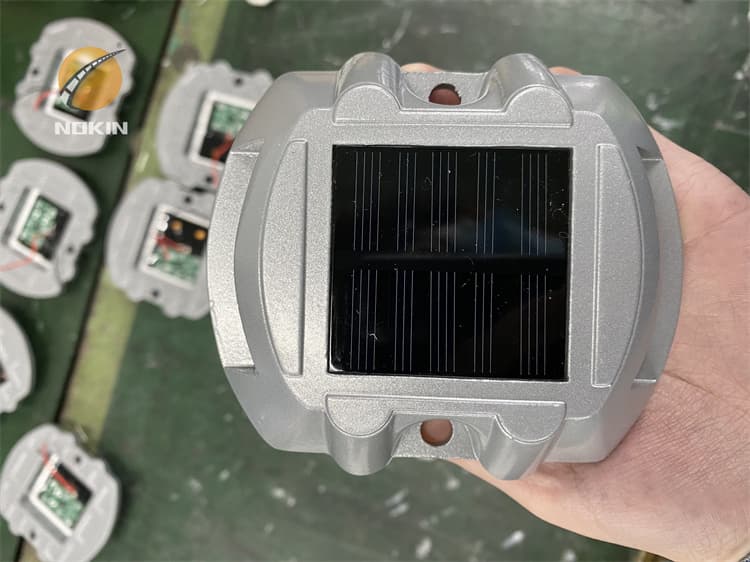

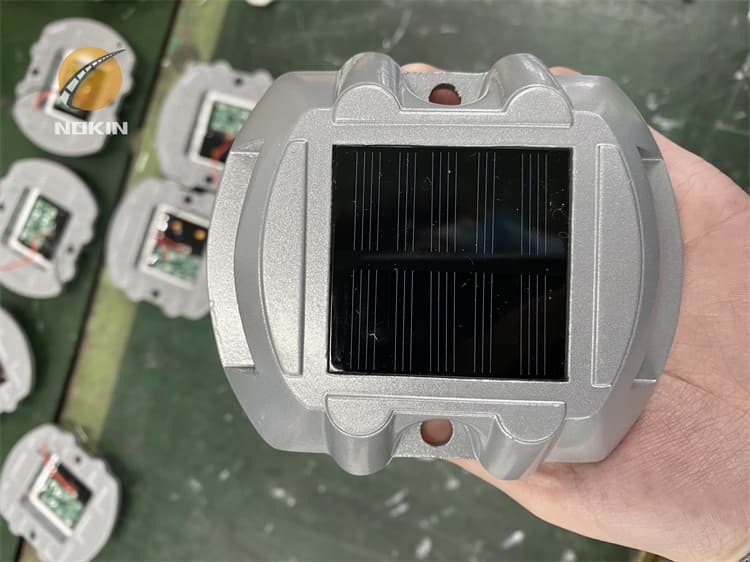

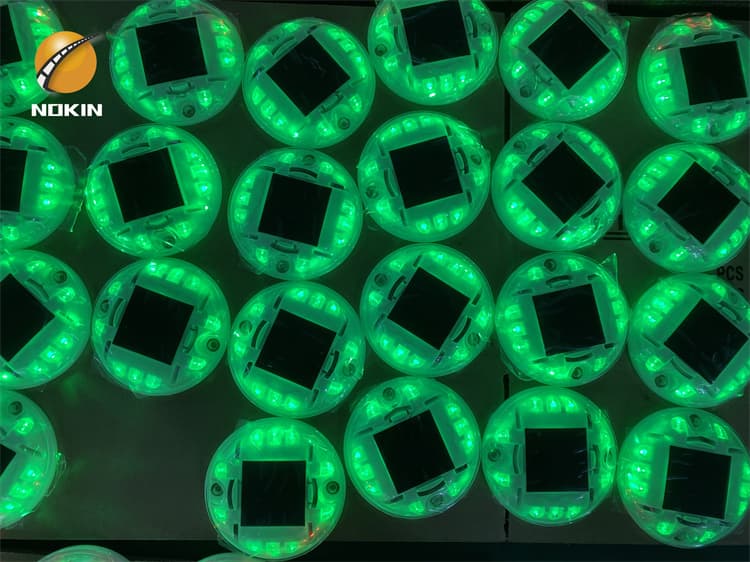

Embedded solar road studs are more out of environmental considerations, using solar panels to provide a stable power supply for self-sufficiency, not dependent on city cables. Common solar road stud lights generally use monocrystalline silicon solar panels, and the photoelectric conversion efficiency can reach about 14%. The solar panel is used as the charging component, the battery or capacitor is used as the energy storage component, and the road stud product adopts LED light-emitting or combined with passive light-emitting.

Embedded solar road studs are more out of environmental considerations, using solar panels to provide a stable power supply for self-sufficiency, not dependent on city cables. Common solar road stud lights generally use monocrystalline silicon solar panels, and the photoelectric conversion efficiency can reach about 14%. The solar panel is used as the charging component, the battery or capacitor is used as the energy storage component, and the road stud product adopts LED light-emitting or combined with passive light-emitting.