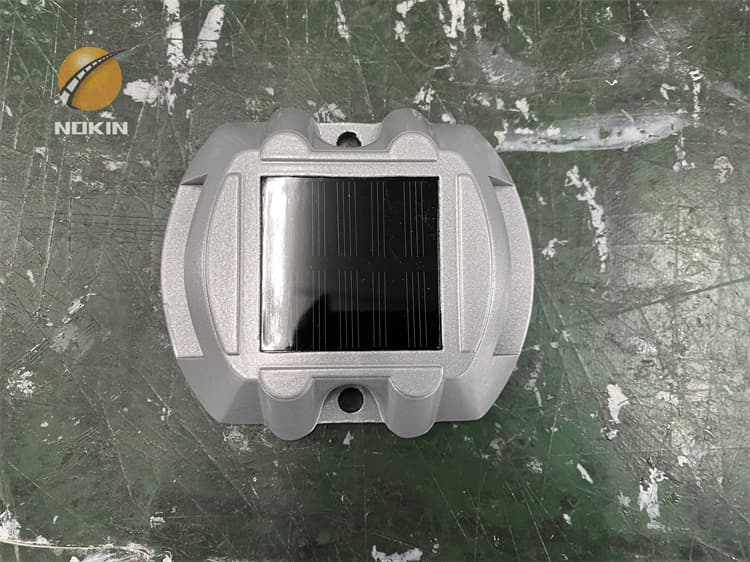

Waterproof Aluminum Road Stud Lights For Airport

Quality tests conducted during the production of solar road spikes are instrumental in guaranteeing their performance and durability. These tests encompass efficiency, battery capacity, LED illumination, water resistance, impact resilience, and regulatory compliance, all contributing to road safety and effectiveness.

Send Inquiry

Quote Online

Share:

Content

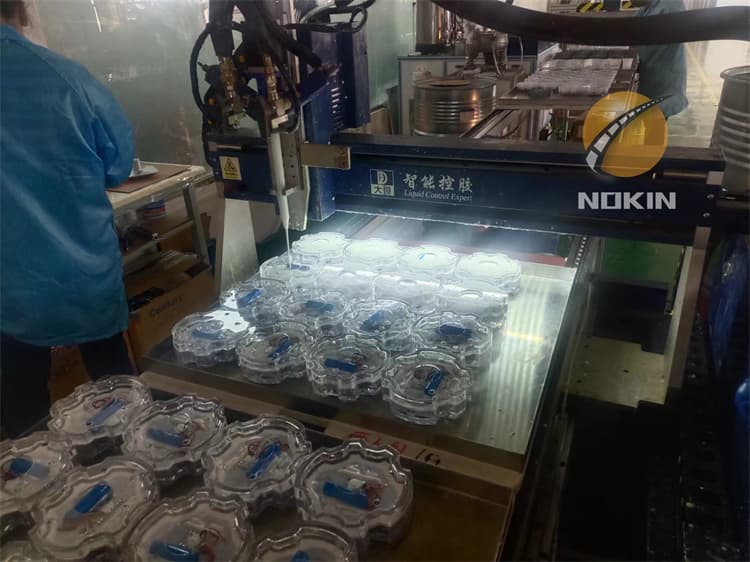

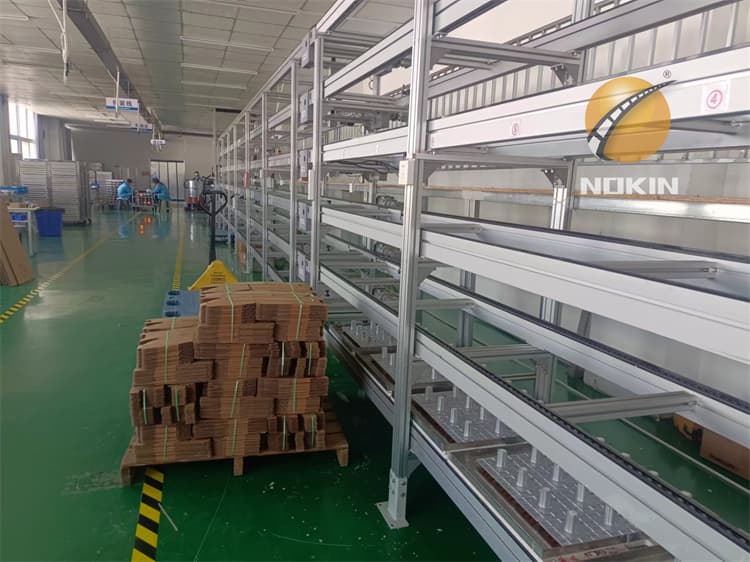

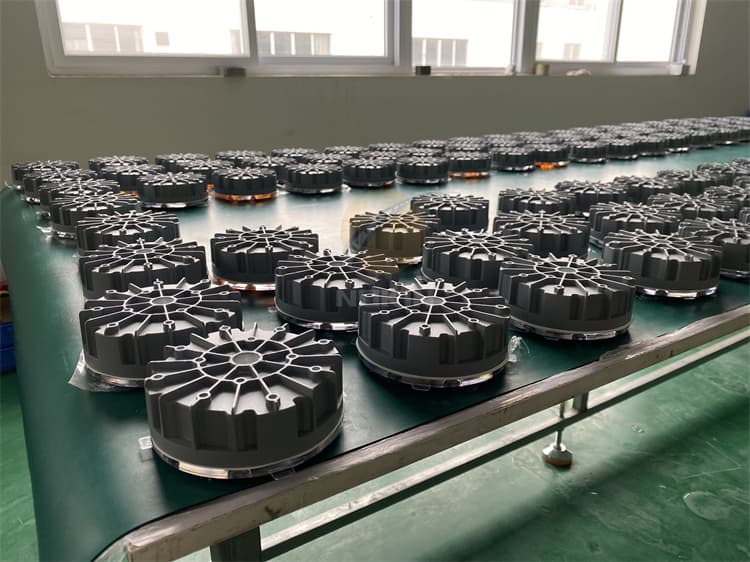

The production of solar road studs involves a meticulous process to ensure their reliability and effectiveness. In this article, we shed light on the battery of tests conducted during the manufacturing of solar road spikes, all aimed at guaranteeing their excellence in performance and durability.

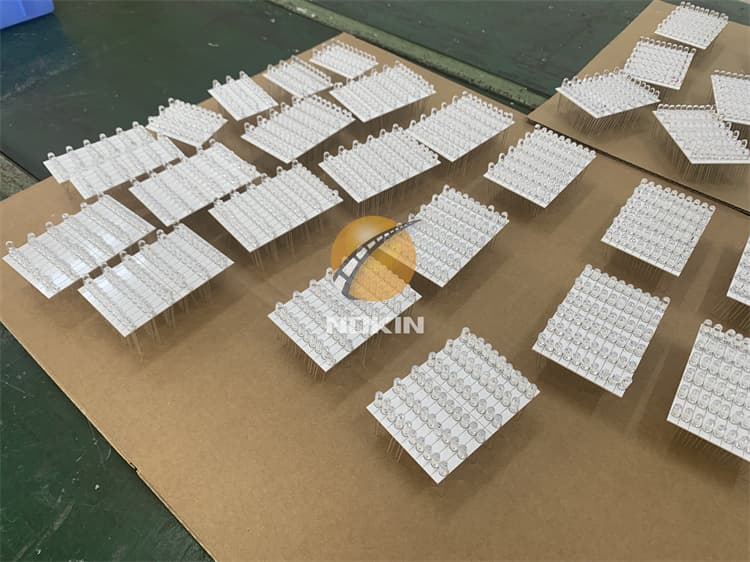

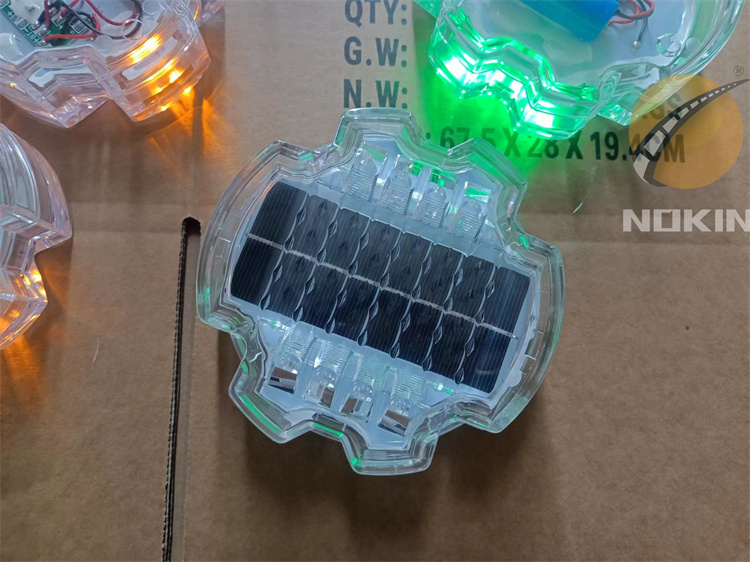

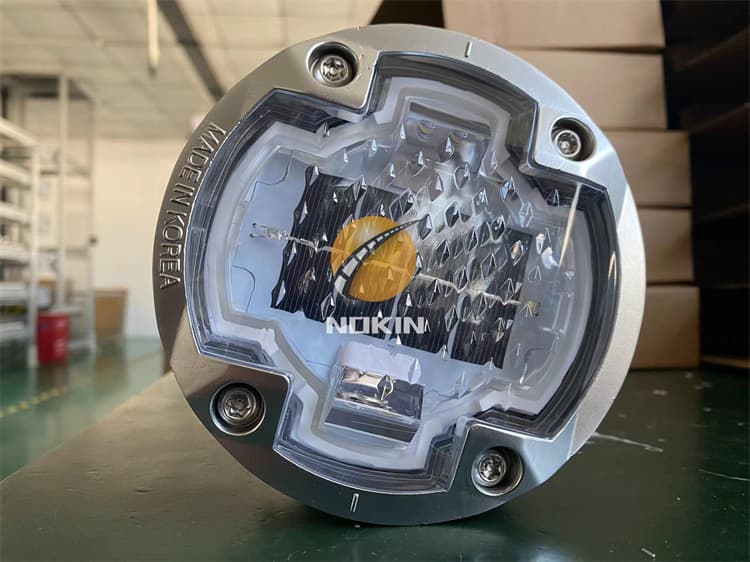

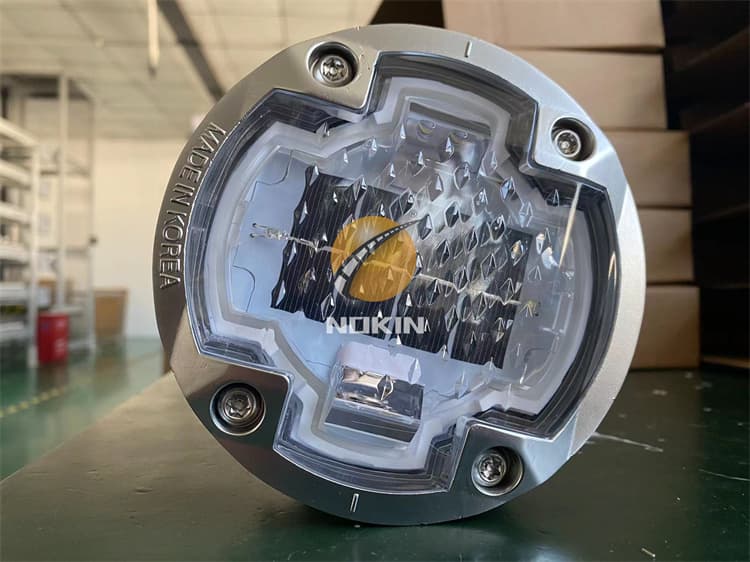

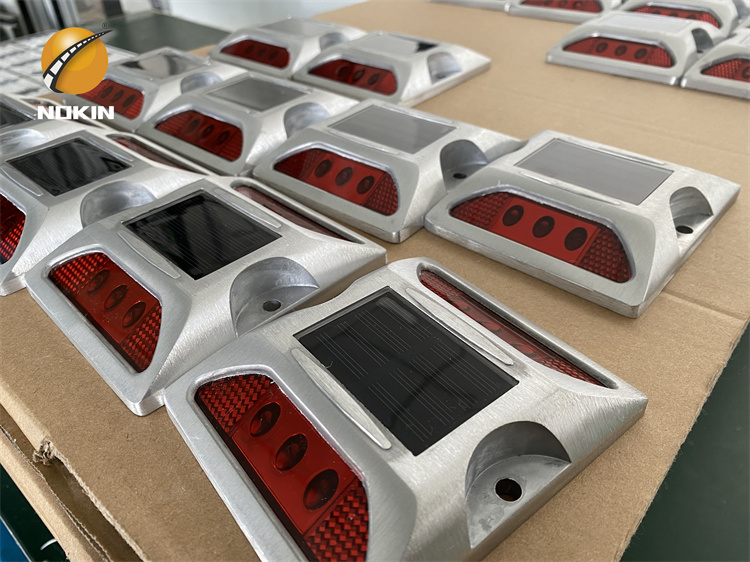

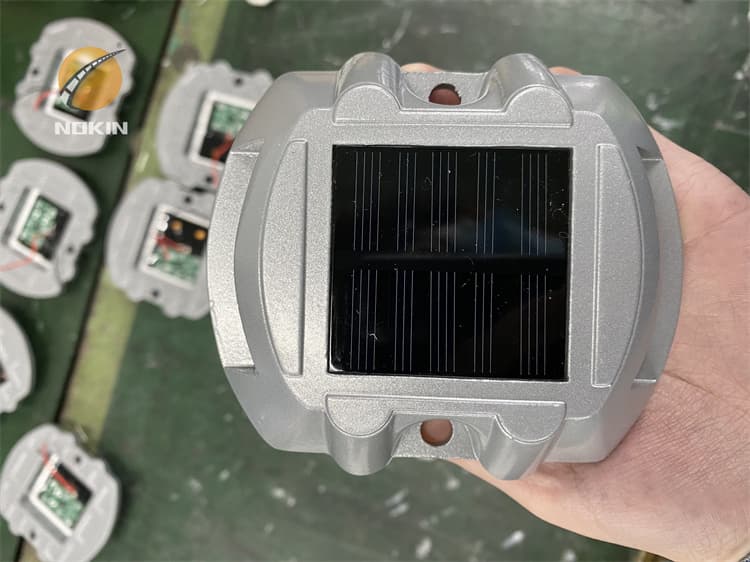

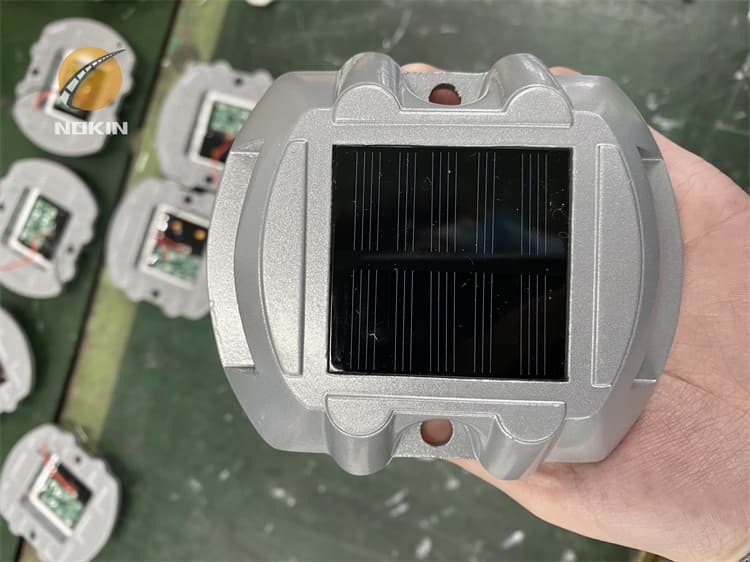

1. Solar Panel Efficiency Tests: Efficiency is paramount for solar road spikes. We explore the tests performed to ensure the solar panels efficiently harness sunlight for power generation.

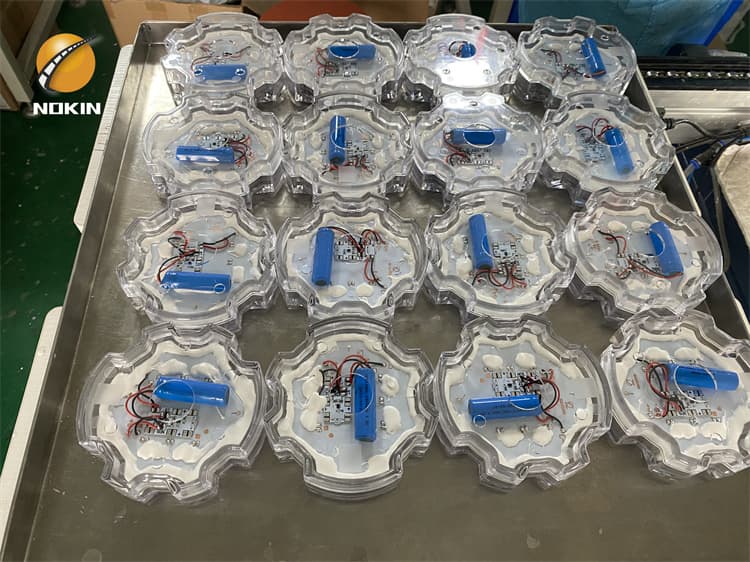

2. Battery Capacity and Durability Tests: The capacity and durability of the embedded batteries are critical. We delve into the tests that evaluate the battery’s ability to store energy and its longevity.

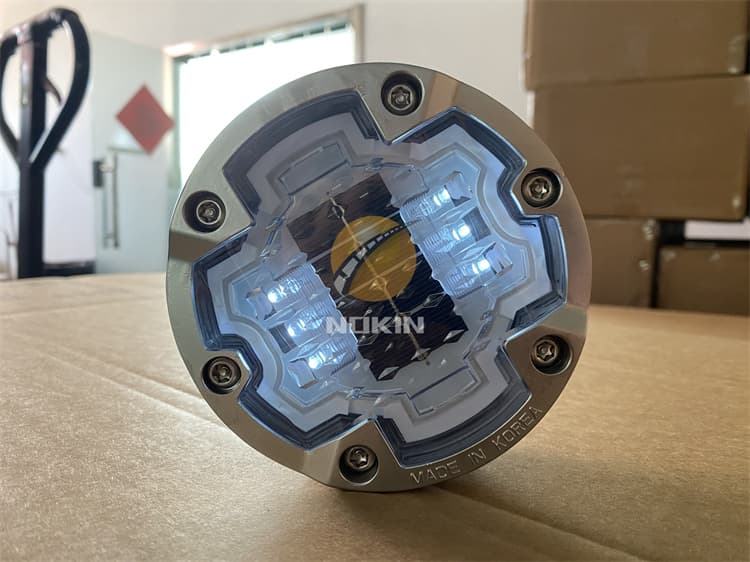

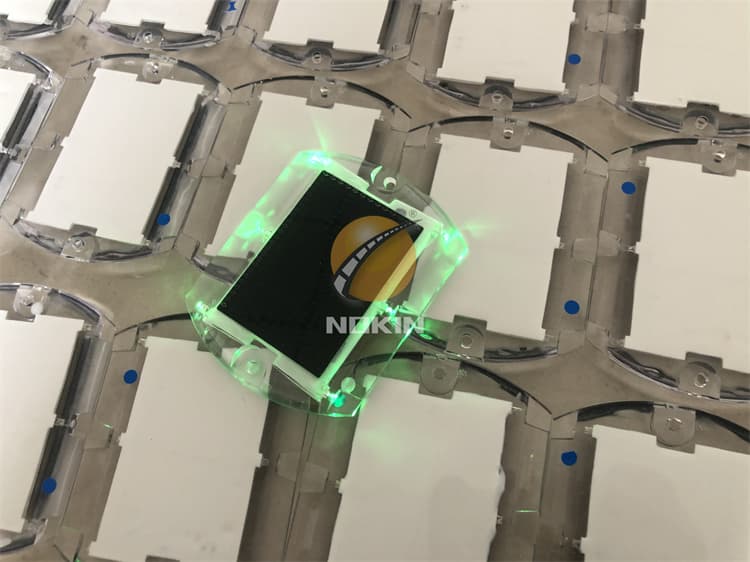

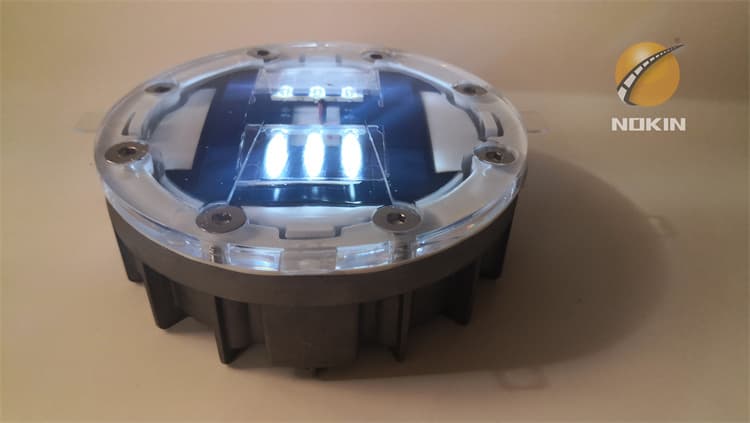

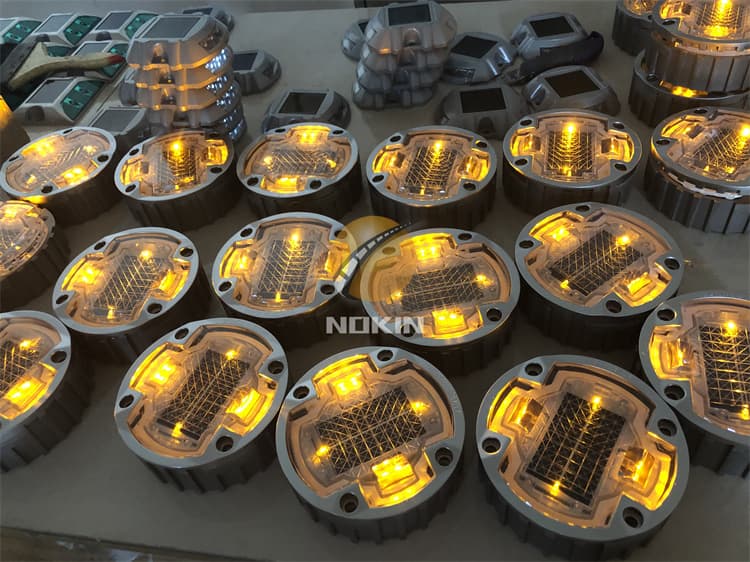

3. LED Illumination Tests: The illumination provided by solar road studs is scrutinized through various tests, ensuring that it meets visibility and brightness standards.

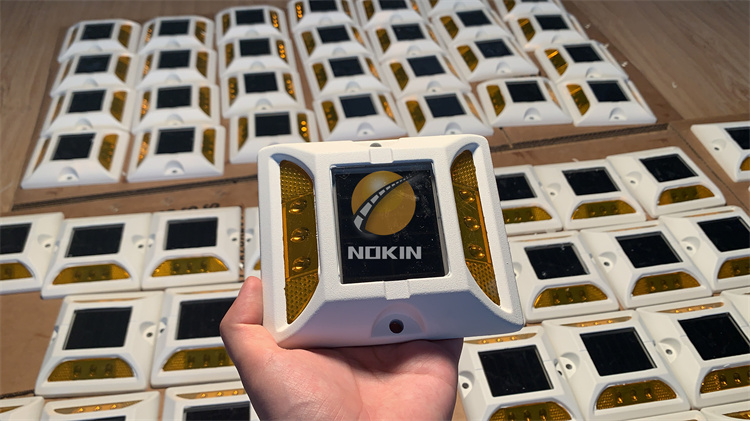

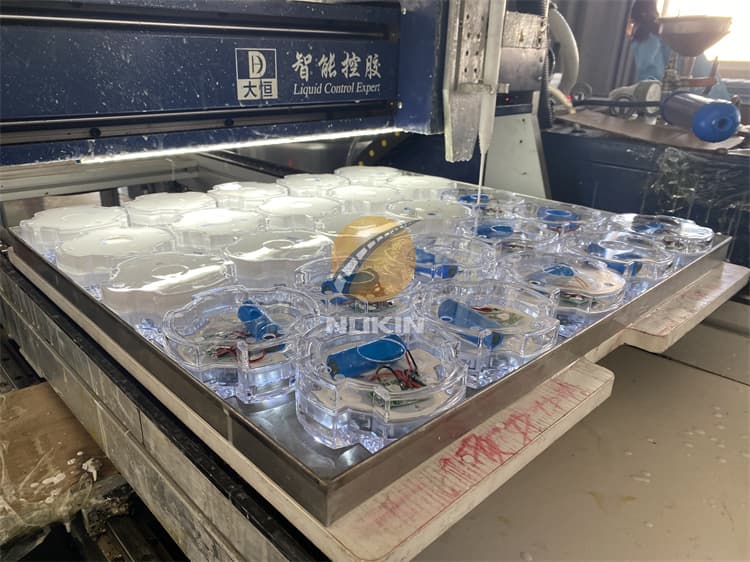

4. Water and Weather Resistance Tests: Solar road spikes must withstand rain, snow, and harsh weather conditions. We discuss the tests that evaluate their resistance to moisture and environmental elements.

Quality tests conducted during the production of solar road studs are instrumental in guaranteeing their performance and durability. These tests encompass efficiency, battery capacity, LED illumination, water resistance, impact resilience, and regulatory compliance, all contributing to road safety and effectiveness.

Inquiry

More