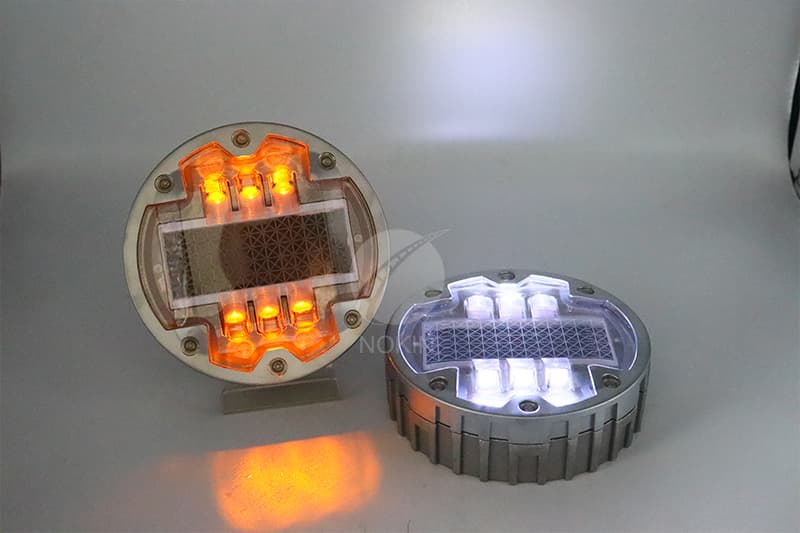

IL300 warning stud reflective for walkway Installation

The road surface on which the solar road studs are installed should be clean, dry and free of dust or loose matter. Not recommended for ambient temperatures below 5°C. Solar road spikes must not be applied to wet surfaces. To activate the full performance of the adhesive, the road surface should be gently preheated to a temperature of 50°C (hand hot), care must be taken to ensure that the road surface does not overheat, as this can damage the surface. If the prevailing ambient temperature conditions are low, the adhesive pads attached to the studs should be heated above 10°C.

The road surface on which the solar road studs are installed should be clean, dry and free of dust or loose matter. Not recommended for ambient temperatures below 5°C. Solar road spikes must not be applied to wet surfaces. To activate the full performance of the adhesive, the road surface should be gently preheated to a temperature of 50°C (hand hot), care must be taken to ensure that the road surface does not overheat, as this can damage the surface. If the prevailing ambient temperature conditions are low, the adhesive pads attached to the studs should be heated above 10°C.

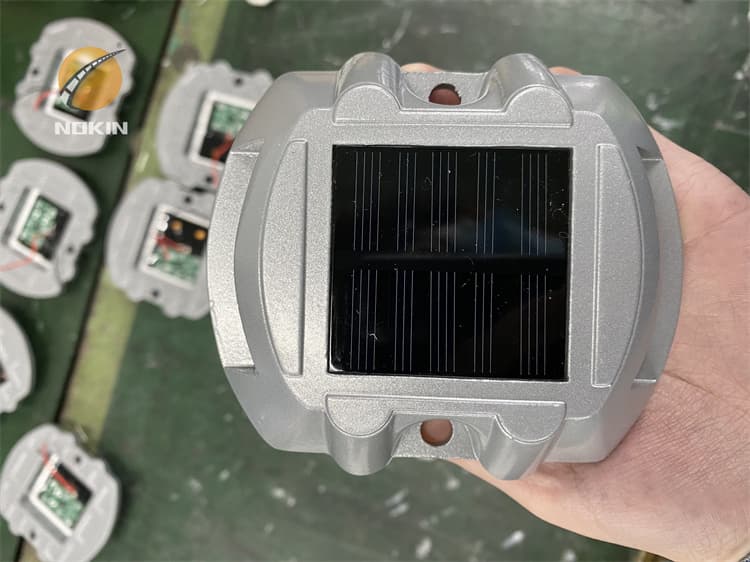

The release paper on the bottom of the solar spikes should then be carefully removed and the studs placed in place. Firm foot pressure should be applied to the solar road studs immediately to ensure good contact with the surface. The vehicle should then slowly run over the applied studs so that a small drop of adhesive appears around the bottom of the solar road stud. Adhesion enhancers may be found to be beneficial when applying studs to certain surfaces and severe weather conditions. Application, as above, but after heating the surface, the following additional instructions should be noted.

Solvent based adhesives can be applied to the load bearing surface where the solar road studs will be placed, it is important that the adhesive is tack cured prior to applying the solar road studs. The application of adhesive improves the performance of the stud, especially in severe weather conditions. The installed solar road studs should be allowed to cure before opening to traffic.

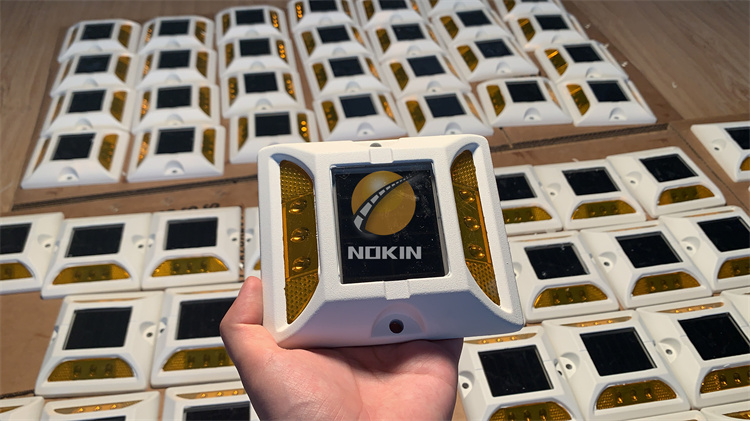

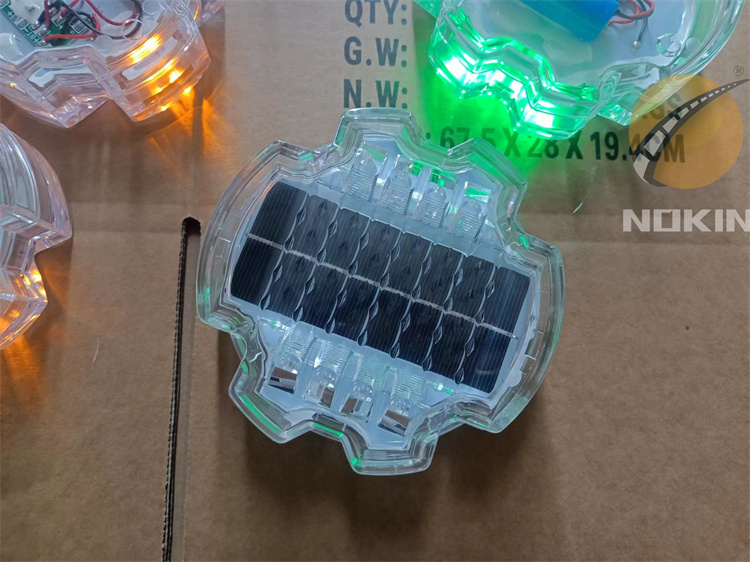

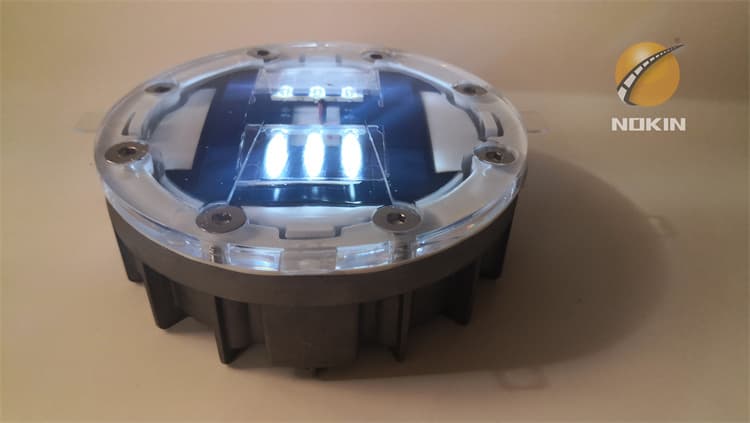

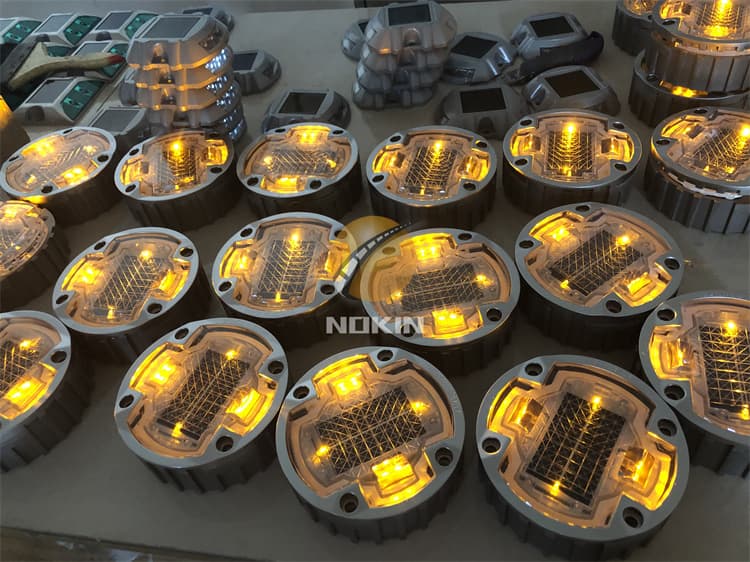

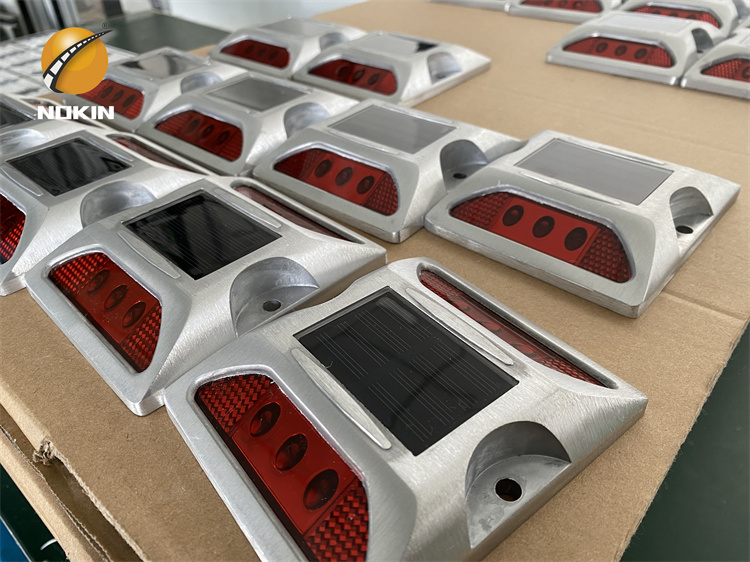

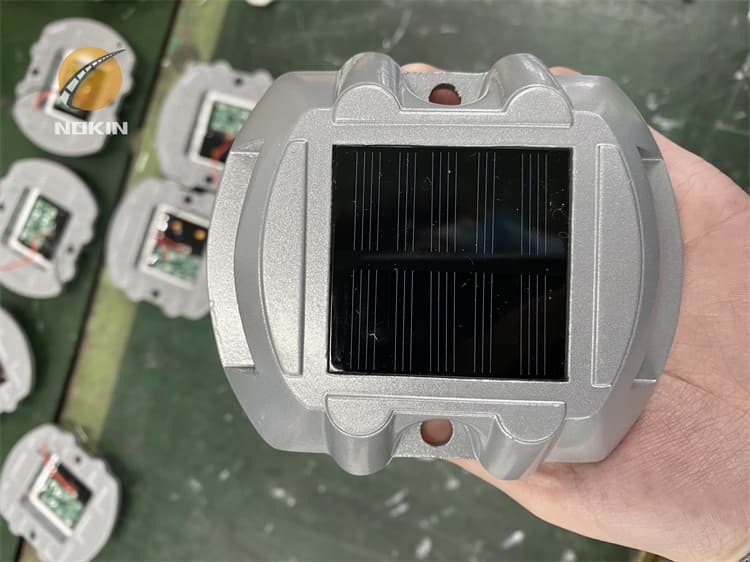

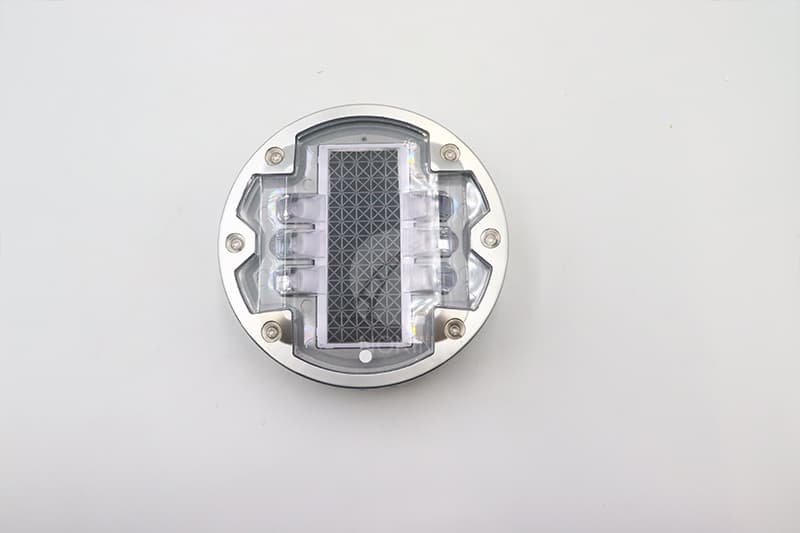

- Minimal traffic over run noise

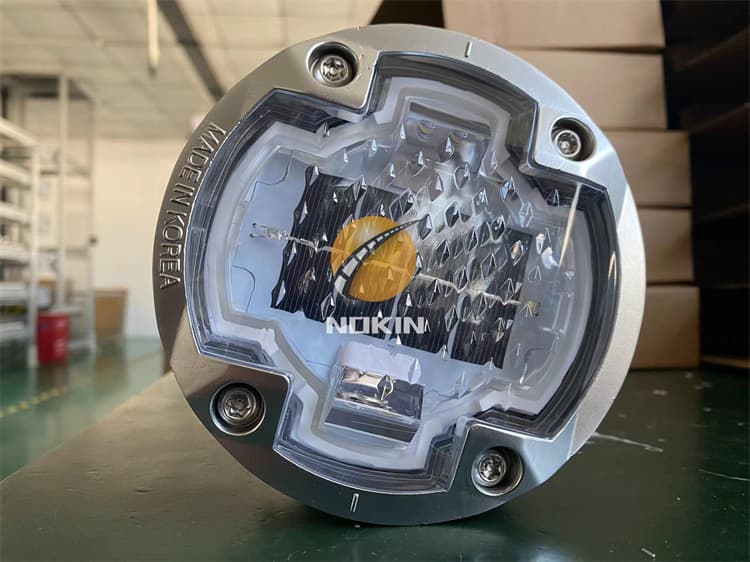

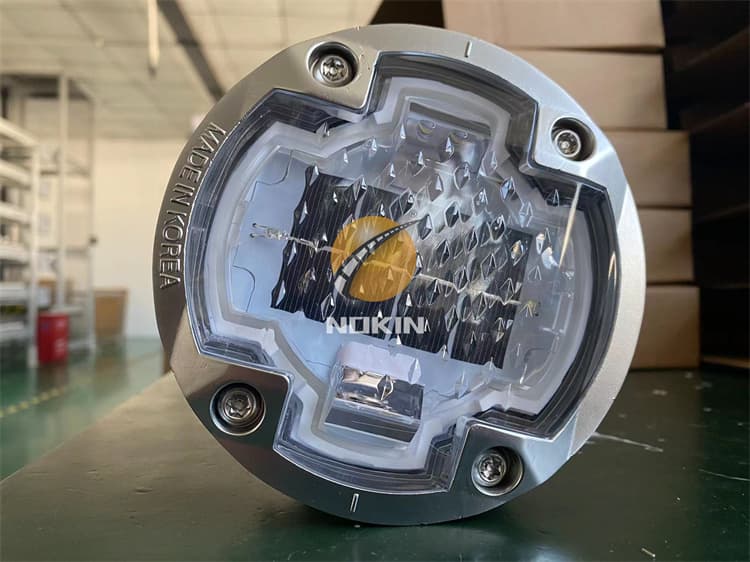

- Body of stud allows day-time visibility

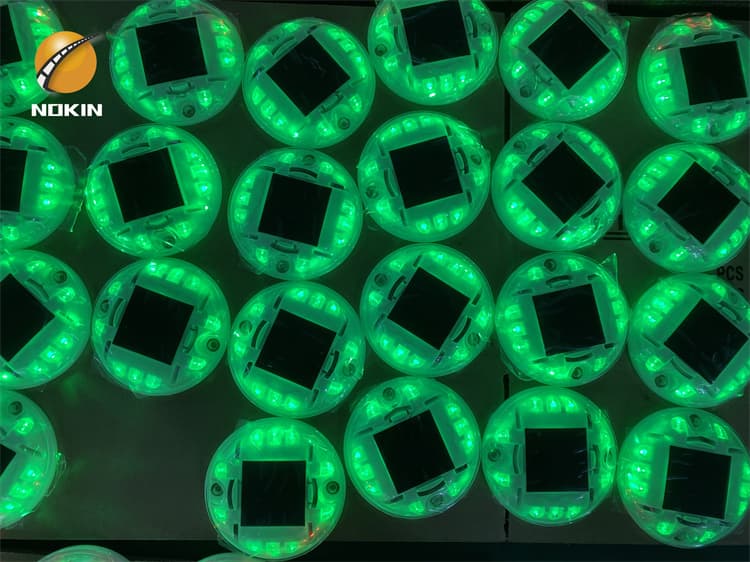

- High outputs thereby minimising traffic disruptions

- Self adhesive or hot melt option available

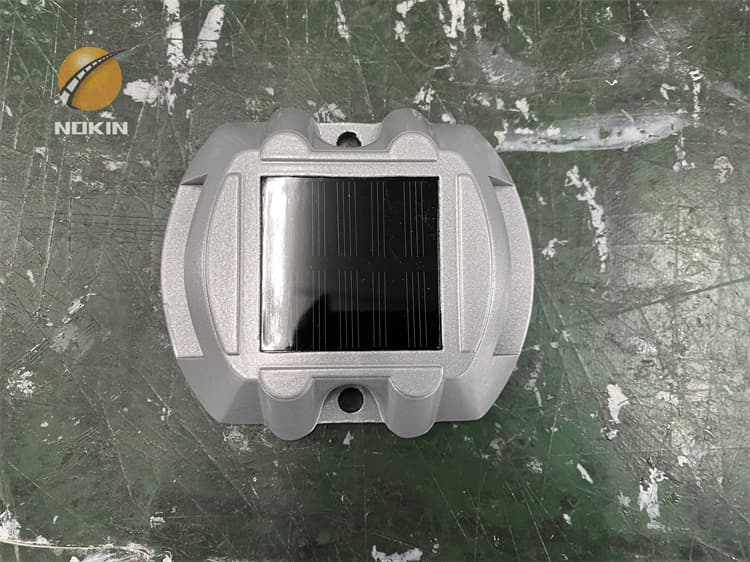

- Low profile – 12mm above the road surface

- Low cost alternative to temporary road markings

- Easy to install and remove